The application of information

Stainless steel welded pipe features

Stainless steel welded pipe is mainly produced by continuous forming unit and UOE method. For thin wall pipe diameter below φ219mm, continuous forming method is usually adopted. For pipe diameter above φ219mm, UOE method is usually used to produce.

The continuous molding unit usually adopts single gun, multi gun or plasma and TIG composite welding process. UOE method is suitable for the production of large diameter, thick wall stainless steel pipe, the length of about 6 meters. Generally using plasma, plasma and TIG composite, plasma, TIG, submerged arc welding combined method, suitable for different wall thickness of steel pipe welding.

Stainless steel welded pipe is used in chemical, petrochemical, food, paper and many other industries.

For pipes with higher inner wall requirements, it can be obtained through the welding process of inner wall remelting.

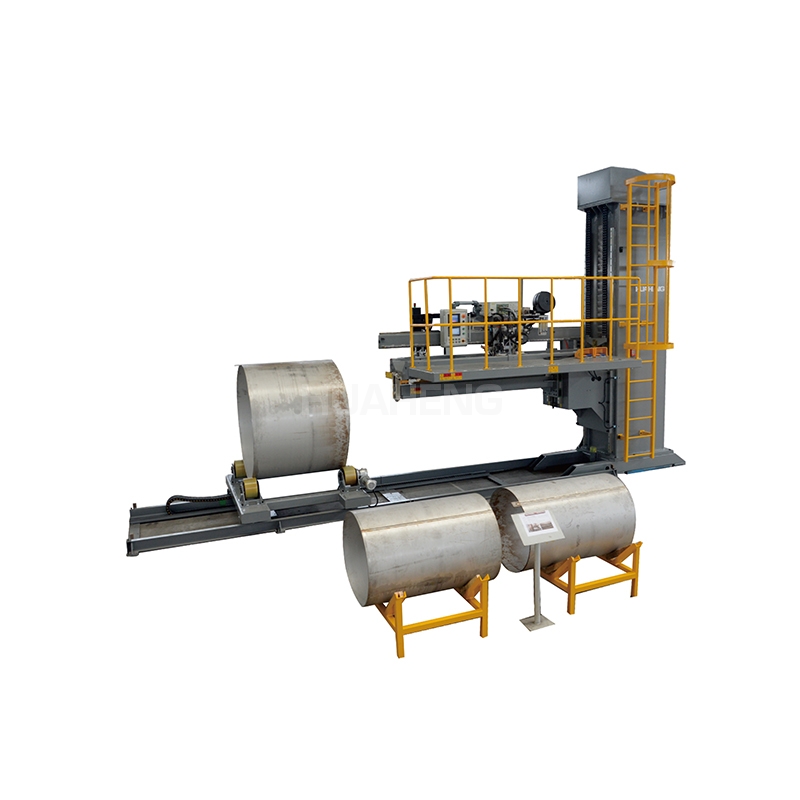

UOE welded pipe:

Diameter of welded pipe: φ219-φ1200mm

Welded pipe length: generally less than 6 meters, except special

Thickness of welded pipe: 4-14mm

Material: SUS321, SUS304, SUS316, SUS316L and so on

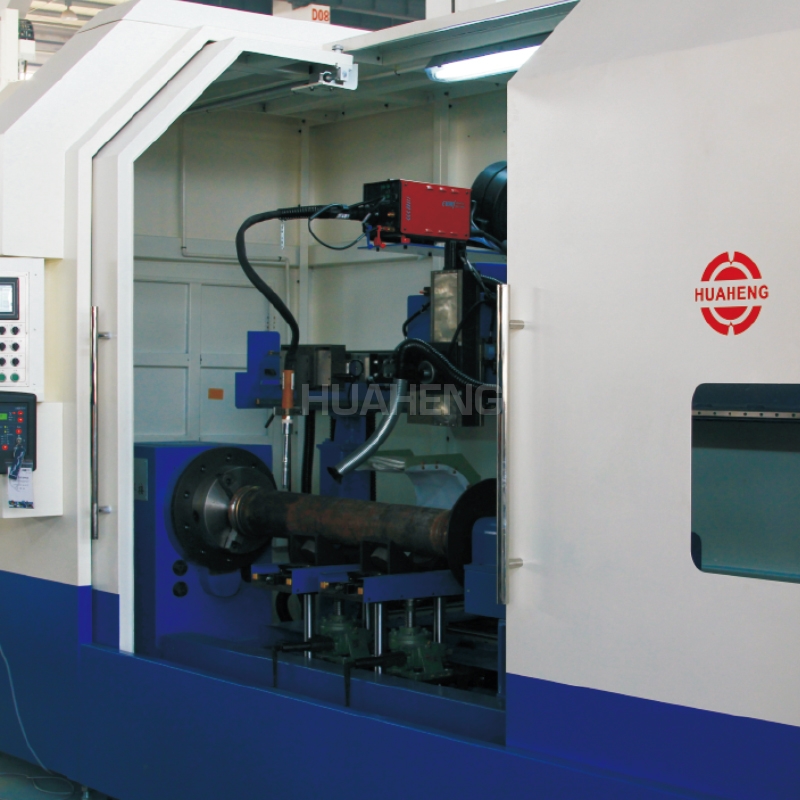

Welding method and characteristics

Because the wall thickness is above 4mm, the plasma welding process is adopted, which has the advantages of energy concentration and strong penetration ability (3-8mm can not open the groove, one time penetration), so as to realize single-side welding and double-side forming. For the pipe with wall thickness above 8mm, the plate slope can be left with blunt edge, and the plasma substrate can be used, and the plasma cover surface /TIG cover surface/submerged arc welding cover surface can be selected according to the plate thickness and welding process. Can also use plasma and TIG welding process at the same time, the current application is more in front of the single gun and other sub-welding process.

中文

中文