The application of information

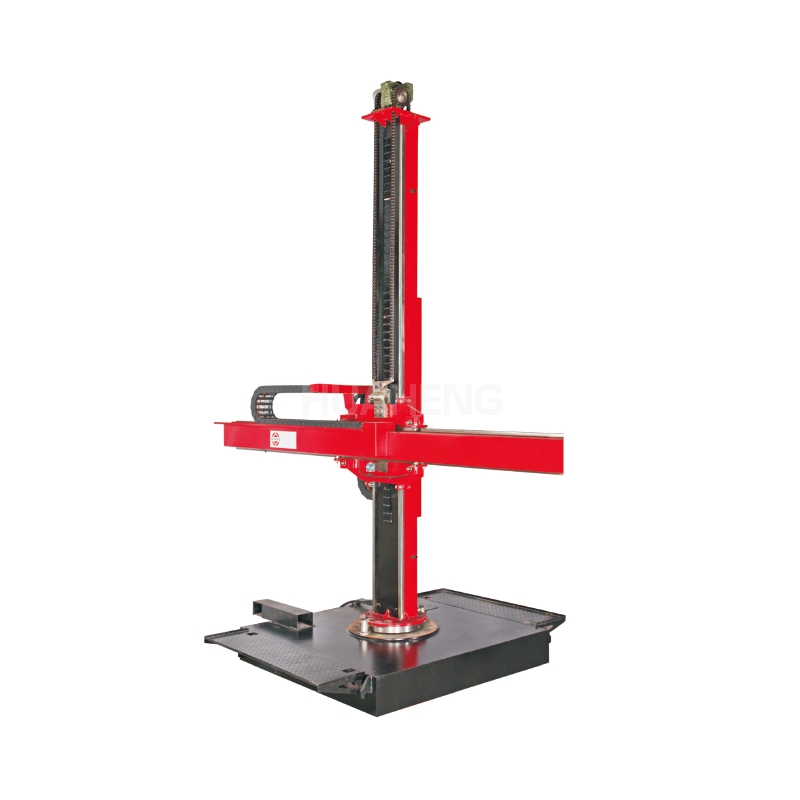

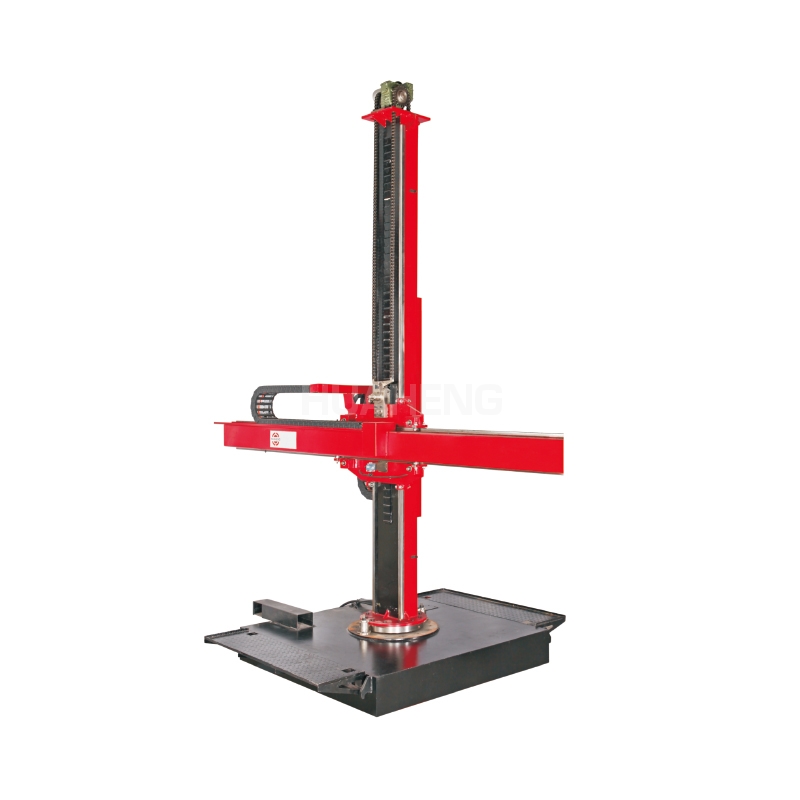

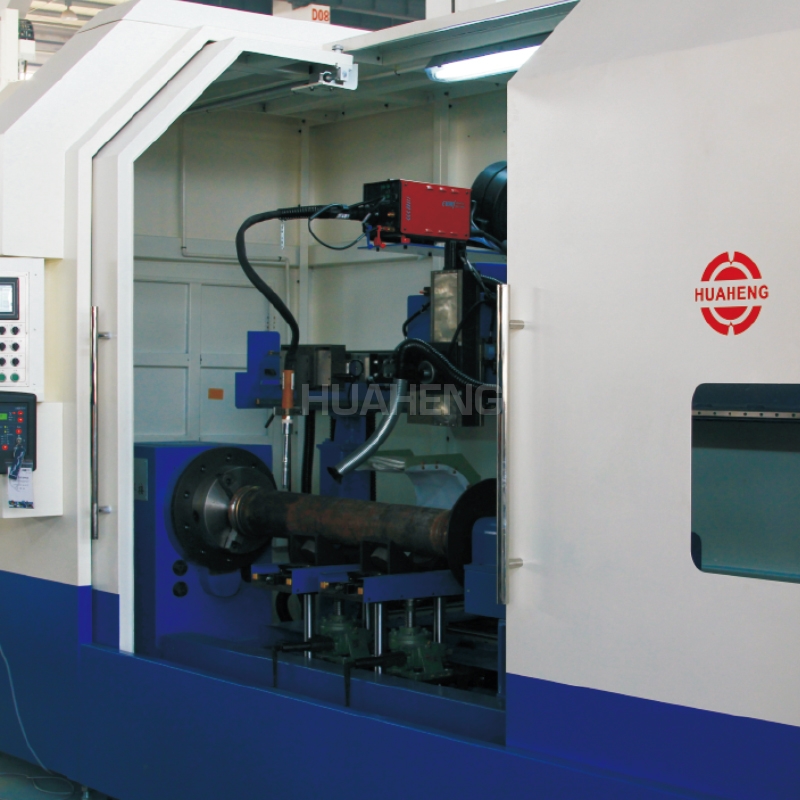

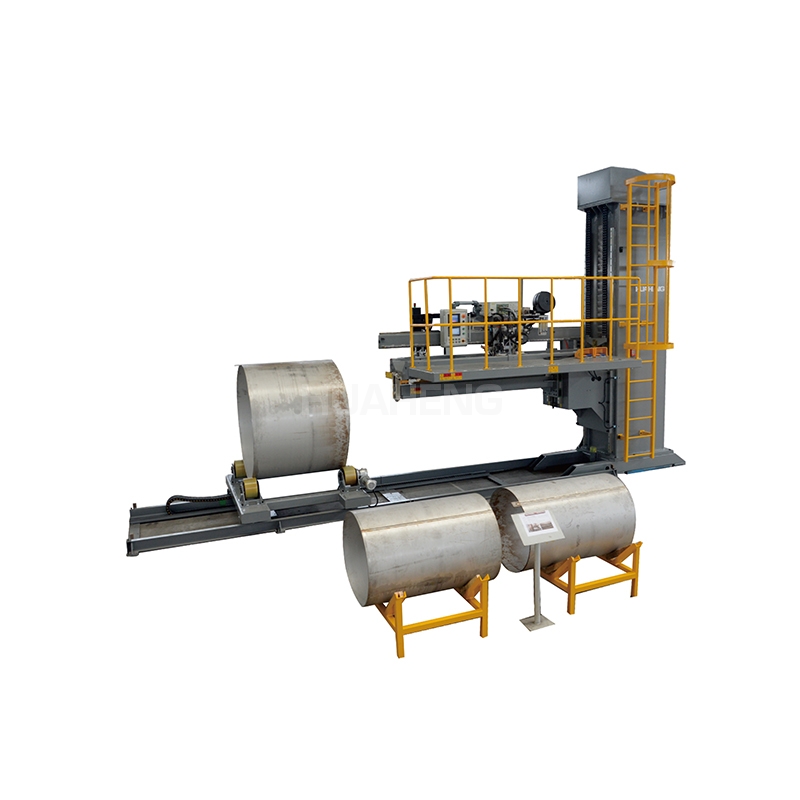

Welding system | Large panel system, inner longitudinal seam and circular seam P+T system |

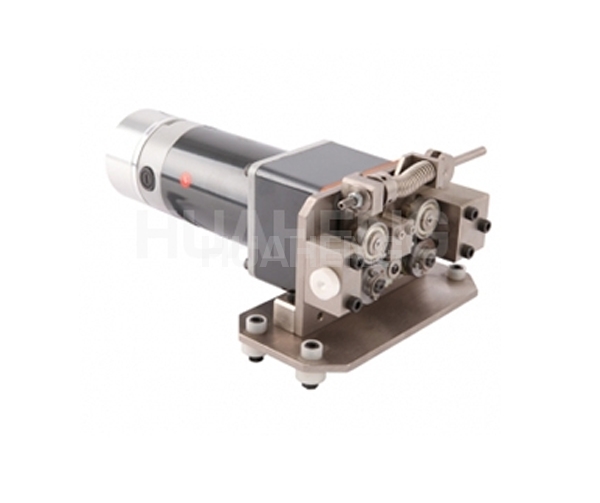

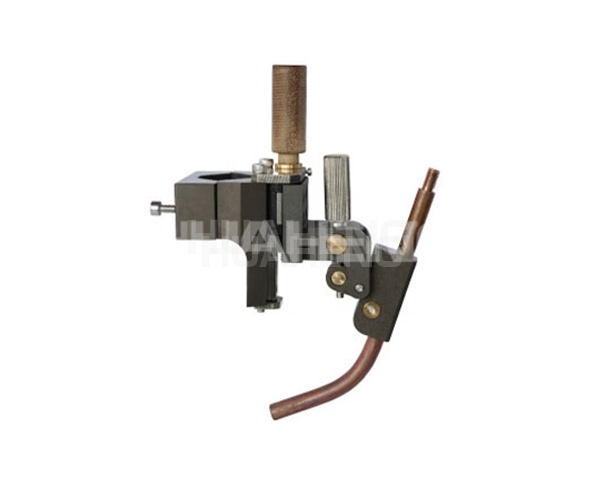

Welding process | P+T (plasma +TIG composite) |

The workpiece material | Stainless steel |

The length of the tank | 5000-7000mm |

Tank diameter | ¢1500~¢2300mm |

The thickness of the material | 3-10mm |

Weld form | docking |

Application industry | Tank box industry, etc |

System Features:

According to the product characteristics of the industry, we specially designed the tank and box welding production line, mainly composed of large plate system, longitudinal seam system, ring seam system;

Using plasma +TIG composite welding, plasma substrate, TIG cover surface, can more effectively use the penetration ability of plasma and TIG welding free arc has good coverage ability, and then with the right amount of filling metal, to achieve the front molding beautiful effect, is a single gun welding efficiency of 1.3-1.5 times;

Each production line is generally composed of one panel and one inner longitudinal seam and ring seam, but according to the workload, it is better to have two panels, one inner longitudinal seam and two ring seams. This configuration can probably produce 10-12 standard cans per day.

The stable industrial control platform is adopted to ensure the stable operation of welding system for a long time.

Building blocks modular design, reduce system design and production cycle, conducive to large-scale production or maintenance;

Huaheng has more than ten years of experience in plasma application, professional training materials, and perfect process guidance and service ability;

Huaheng has experience in supporting tank and box production lines, and has successfully provided equipment and technology for 4 companies in China.

The system is a turnkey project.

中文

中文