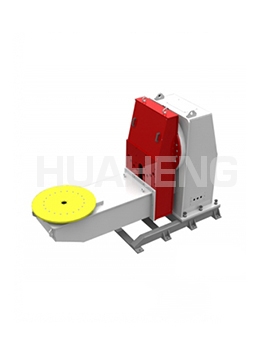

The application of information

Application of M90 in shaft sleeve welding of construction machinery

1. Type of workpiece

Shaft and sleeve mechanical devices at hinged joints of construction machinery

2. Joint form

Fillet weld

3. Pipe diameter range

63 - Φ Φ 150 mm

4. Welding machine method

MAG welding

5. The importance of shaft sleeve welding and the advantages of automatic welder

I. There are many hinge points on the construction machinery device, and the shaft and sleeve at the hinge point are the key parts of the mechanical device

Ii. When working, the shaft and sleeve are relatively rotating and the transfer load is large, so the welding of the shaft sleeve is one of the main welds in the structural parts, and its fastness directly affects the reliability of the excavator

Iii. Inferior welds will lead to tears at the shaft sleeve welds, which are generally difficult to find and very difficult to repair once cracks occur

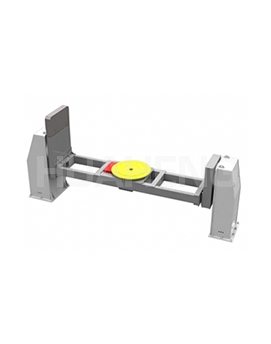

Iv. The workpiece only needs to be placed in any horizontal position to stay still, without long installation time

V. When welding at both ends of the same workpiece, just move the welding torch

Vi. Automatic welding, good reproducibility of weld quality

Vii. Welding Angle generally can meet the requirements of 9-10mm in one welding

Viii. The appearance of the weld is of good quality, and no treatment is needed

中文

中文