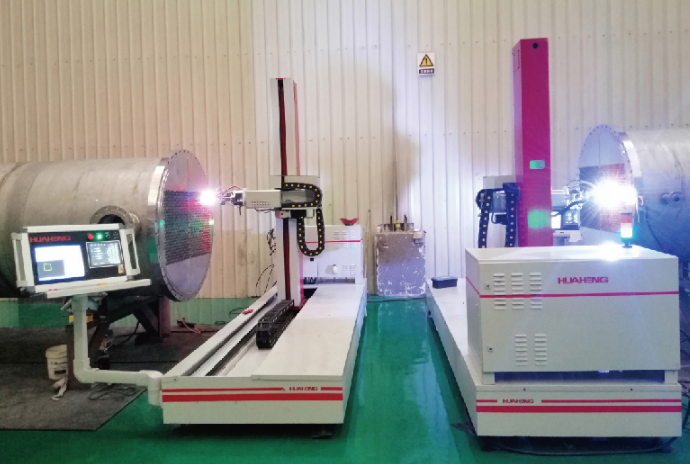

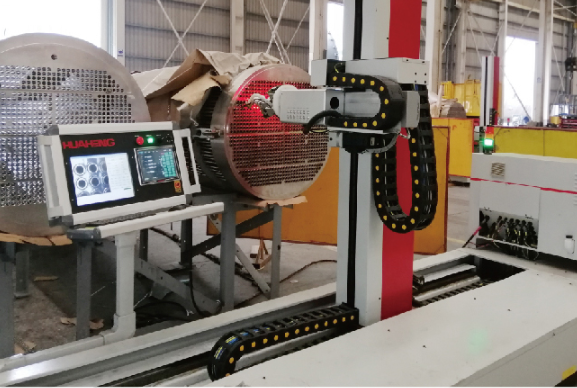

Huaheng Intelligent Tube Sheet Robot Welding System

发布日期:2021-11-12 作者: Marketing Office 点击:

In the process of transformation and development of my country's traditional manufacturing industry to intelligent manufacturing, intelligent manufacturing has become an important strategy for the transformation and upgrading of the manufacturing industry. The tube sheet intelligent robot welding system independently developed and manufactured by Huaheng adopts advanced and precise visual positioning control technology to realize a truly unmanned automatic tube sheet welding robot, which provides a guarantee for the realization of automated and intelligent welding in the manufacturing industry.

Intelligent tube sheet robot welding system

| TPR2000 size(mm) | 4200*1340*3040 |

| TPR2000 size(mm) | 5000*1340*3940 |

| Welded pipe range(mm) | φ10~ diameter 80 |

| Welding current(A)/ Position of welding | 5~500/ All position welding |

| Welding material | Carbon steel, stainless steel, titanium alloy |

| Connector form | Tube flush, tube extended |

| welding process/ Welding layers | TIG Self fusion or wire addition/multi-layer welding |

| Shielding gas/cooling method | Argon/water cooling |

| Welding tool angle range | -10°~30° |

| Tungsten electrode/wire diameter(mm) | φ2.4、φ3.2/φ0.8~1.0 |

The system adopts Huaheng's advanced automation equipment and mature welding process. It is mainly used in automatic welding of various tube sheets in chemical, heat exchanger, boiler, power plant, military and nuclear power industries.

Performance characteristics

Improve labor productivity. The tube sheet intelligent welding robot will not get tired, it can work 24 hours a day without interruption. In addition, with the continuous application of high-efficiency and intelligent welding technology, the production efficiency of using welding robots is more obvious.

1、The equipment positioning time is about 7S;

2、The equipment is equipped with arc length tracking;

3、The equipment is equipped with arc length tracking;

1、The equipment positioning time is about 20S;

2、The device rarely has arc length tracking;

3、The welding stroke is 1.5M*1.5M

Huaheng CNC tube sheet welding system is specially designed for tube tube sheet, adopts advanced and precise visual positioning control technology, equipment positioning, arc length tracking and welding stroke are closer to the welding site. Ensure efficient, stable and reliable welding quality.

中文

中文