Huahengs cloud platform and application based on 5G technology

发布日期:2021-11-26 作者: Marketing Office 点击:

At present, the welding process exploration cycle of petrochemical, pressure vessel and other industries is long and the task volume is large. When welding different types of workpieces in the welding workshop, the relevant welding parameters need to be automatically explored, and the database upgrade also needs to be on-site, which is inefficient. In order to manage welding equipment more conveniently, and at the same time combining the increasingly important information technology, Huaheng Welding has created a set of industrial Internet welding cloud platform.

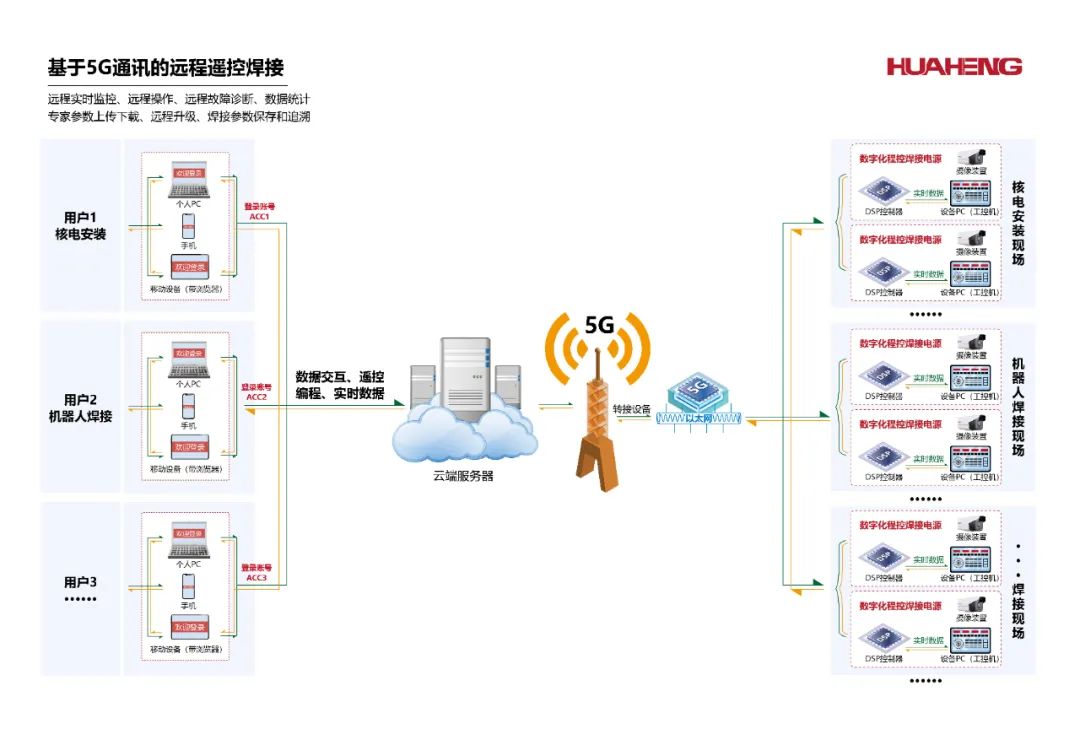

The welding process of the 5G welding cloud platform, supported by a large amount of process data, establishes a relationship model between welding process parameters and welding joint performance, forms a welding process database, and realizes cloud storage of welding process data based on the previously established 5G and welding cloud platform. And cloud computing, users can download the required welding parameters through the welding cloud platform according to their own workpiece information (pipe, diameter, wall thickness, etc.) to guide welding production.

Huaheng has been focusing on the manufacture of welding automation equipment. The systems involved in precision welding and robot welding are in a leading position at home and abroad, and have been applied by more than 5,000 customers.

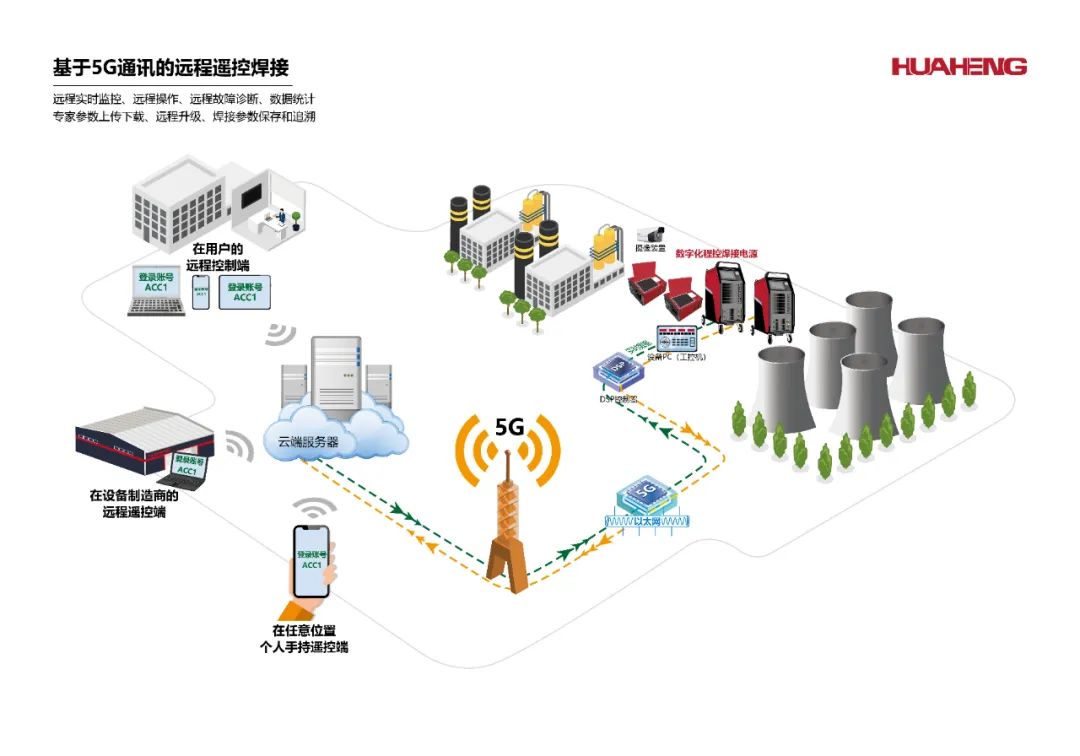

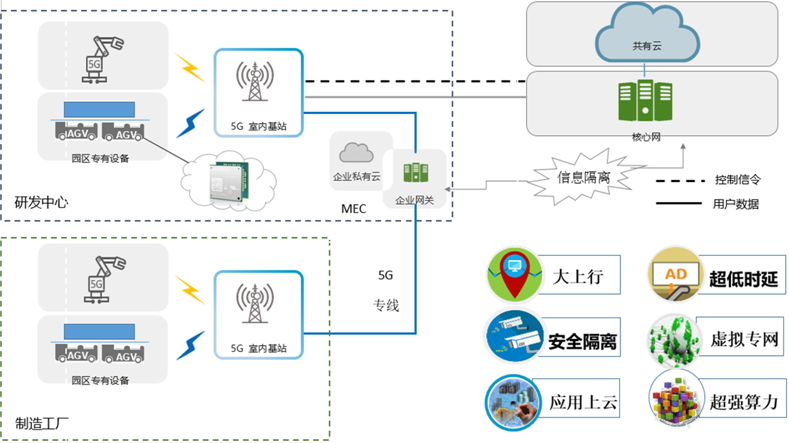

The huge customer network, with the intervention of industrial 5G technology, makes the debugging and service of our welding equipment close at hand: the real-time video of the scene is transmitted through 5G, and the welding status of the scene can be seen without delay → remote control of the equipment Operation and maintenance, the delay within 20ms can ensure that each action is accurate → Our welding cloud platform can collect and analyze the data of our welding equipment scattered in various places in real time and analyze and process it in the cloud, allowing Huaheng's welding expert database more accurate and authoritative.

Huaheng Welding Cloud Platform is based on C/S architecture, which is stable, mature and widely used;

URL:icould.huahengweld.com;

Each user has its own account, and it is necessary to log in to the account to manage the welding equipment under this account. One or more devices can be managed under one account;

You can log in through a browser through various networked devices, such as computers, mobile phones, Pads, etc.;

The successful implementation of "Huaheng Welding Cloud Platform Based on 5G Technology" can directly promote the informatization of the company's related welding equipment:

1) Conducive to the effective management of various welding equipment by the company management;

2) It is conducive to the sharing of process data by the process department;

3) It is helpful for the production department to grasp the use status and production efficiency of the equipment in time, and provide data support for the assessment and settlement;

4) It is conducive to real-time interaction between users and manufacturers, and improves service efficiency.

Huaheng Welding actively explores the application of 5G technology in the field of welding technology, reduces the manpower consumed in the welding process, and solves the problems of long exploration cycle and large number of tasks in the current welding process of petrochemical, pressure vessel and other industries, which greatly saves costs. , improve the efficiency and contribute to the development of the national 5G intelligent manufacturing field.

中文

中文