Hypertherm Ture Bevel Bevel Technology and Huaheng Rotary Head Cutting

发布日期:2020-09-11 作者: Marketing Office 点击:

As we all know, many bevel cuts are straight cut + secondary machining to form a bevel, which is then used for subsequent welding. Hypertherm's True Bevel™ plasma beveling technology can complete fine beveling at one time, which not only saves labor and space, but also improves production efficiency and automation level, and has become the first choice of more and more users.

How does Hypertherm True Bevel™ bevel technology do it?

01 Massive groove parameters

The advantages of bevel cutting are obvious, but the development bottleneck has always been that compared with ordinary straight cutting, bevel cutting requires massive and precise process parameters. Why are these groove parameters needed?

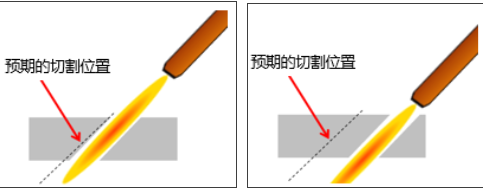

Let's take the cutting height as an example. Under the same conditions, only changing the parameter of the cutting torch height, the cutting sample will change as follows:

Changes in the height of the torch may directly lead to dramatic changes in workpiece dimensions and even produce scrap.

Massive trial cuts must be done for groove parameters. These basic trial cuts require a lot of labor and materials. From every thickness, every angle, and every type of bevel, Hypertherm has repeated tens of millions of times to obtain complete and accurate bevel parameters.

02 Parameter table embedded formula

Trial cutting parameters are fixed, but customer demands emerge in an endless stream.

Taking the Y-bevel as an example, the thickness of the blunt edge is usually a strict requirement, but the existing groove data cannot contain the blunt edge requirements of all sizes. The height of the blunt edge has been measured at 4mm, 7mm and 10mm, and the customer requires 8mm, what should I do?

Hypertherm conducts an in-depth analysis of all parameters and fits them into function formulas, which are built into the database. Customers can adjust the values according to the actual situation to meet their own cutting requirements, and the parameter settings are more flexible.

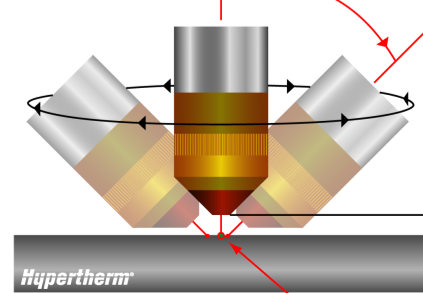

03Hardware deviation processing

The beveling head hardware will wear for a long time, and the change of the hardware will cause the offset of the pivot point of the gun tip rotation. Hypertherm named this pivot point TPL, which is the benchmark for many other parameters. Once it is wrong, it will also cause The size of the workpiece changes drastically. How to solve this situation?

Hypertherm uses a dedicated tool to recalculate the new TPL value in the field. Then adjust the value in the groove parameter table, and all parameters are automatically corrected. Such a combination of software and hardware can ensure that the groove parameters continue to be effective.

Hypertherm True Bevel™ Bevel Technology

As part of Hypertherm's SureCut™ Intelligent Cutting Technology, True Bevel™ bevel technology for HPRXD and XPR plasma cutting systems is a high-performance mild steel cutting technology. The technology is factory tested and easy to use, eliminating the need for users to try and determine the plasma beveling process. With True Bevel™ beveling technology, you can quickly set up new jobs and achieve consistently fine cuts.

Advantage:

· Set-up time for new jobs is greatly reduced and scrap is significantly reduced due to fewer trial cuts and fewer errors.

· Offers bevel cut sequence recommendations to improve accuracy and ensure consistent quality.

· The parameter table has built-in formulas that can be extended and users can easily add new angles.

The Huaheng cutting system rotary head with Hypertherm True Bevel™ bevel technology brings the plasma bevel cutting process to a near-perfect level:

中文

中文