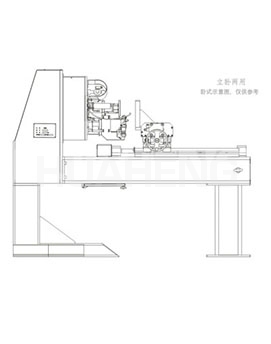

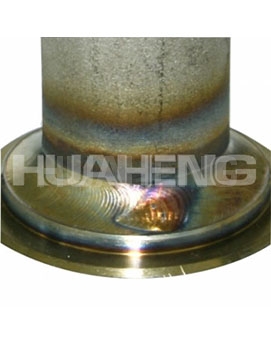

This system is a special system designed for TIG welding of pipe/pipe flanges,and is suitable for automatic welding in the form of general pipe flanges.According to the needs of the welding process,single-position or all-position welding can be achieved;butt welds can be welded,and fillet welds can be welded;self-fusion,wire filling,or self-fusion and wire filling can be selected,which is convenient,fast and labor-saving.It can be placed vertically or horizontally.This machine can be used together with iArc400,408 programmable welding power source,and is suitable for automatic welding of special pipes,pipes and pipe flanges in locomotives,construction machinery and other industries.

Suitable for automatic welding in the form of pipe flanges in the construction machinery and locomotive industries;

According to the needs of the welding process,you can choose to use self-fusing,wire filling,or first self-fusing and then wire filling,etc.,which is convenient,fast and labor-saving;

Vertical or horizontal welding methods can be selected;

The clamp body can be adjusted back and forth through the rocker on the back(lower)side of the hand crank;

The clamp body can be adjusted left and right by hand cranking the rocker on the side of the body;

The drive adopts imported DC motor with stepless speed regulation within the speed range.All water,electricity,gas pipes and lines are free from entanglement;

The pneumatic clamping method is adopted,so that the workpiece can be firmly positioned on the worktable without human intervention;

The standard structure of the cold TIG welding torch is adopted:the tungsten electrode clamp is pressed from the back to the front to achieve the purpose of clamping the tungsten electrode,and it is convenient and quick to replace or adjust the tungsten electrode;

Wire feeding without entanglement,comes with an integrated wire feeder,can be loaded with 1.0kg reel.

With arc length and yaw function.

Weldable material | Carbon steel, stainless steel |

Weldable pipe diameter(mm) | Φ17~Φ76 |

Tungsten electrode diameter(mm) | Φ3.2 |

Spinning speed(rpm) | 0.28~5.6 |

Torch inclination | 0º~45º adjustable |

Protective gas | Argon |

Cooling method | Water cooling |

Cooling flow(ml/min) | ≥600 |

Yaw width(mm) | 40 |

Arc length height(mm) | 40 |

Wire diameter(mm) | Φ1.0(Standard) |

Maximum wire feed speed(mm/min) | 1800 |

Weight(kg) | 290 |

Dimensions(mm) | 700×640×1760 |

中文

中文