The application of information

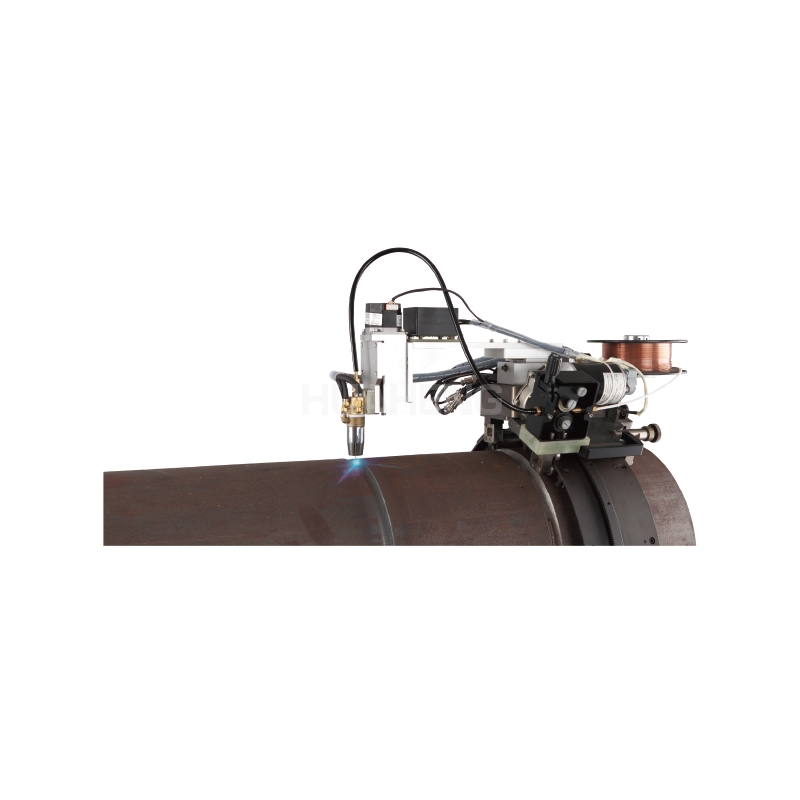

Application of MIGTRACK60 crawler system

1. Type of workpiece

Oil transmission pipeline and branch pipe installation, gas transmission pipeline and branch pipe installation

2. Joint form

Butt weld

3. Range of pipe diameter and thickness

Pipe diameter: φ180-φ1500mm; Thickness: 6 to 20 mm

4. Welding machine method

MAG welding

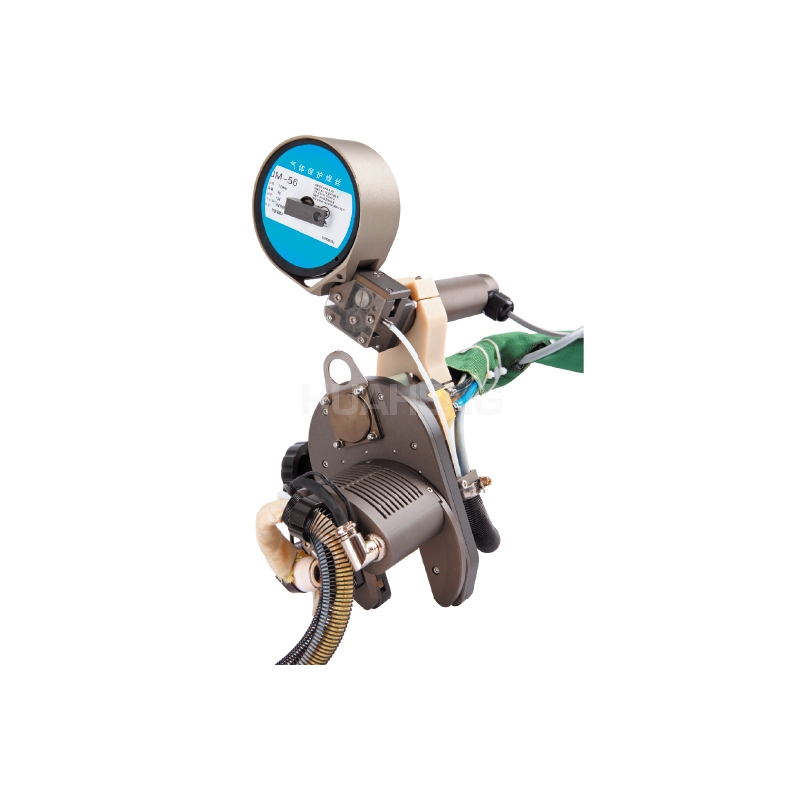

5. Performance characteristics

The MAG welding process is divided into two halves.

Pre-welding state: pre-spot welding is firm, welding groove is finished by machining to ensure the quality of the group.

The pipe butt space is 3mm to 6mm, and the wrong side of the pipe butt is ≦1mm

Gear transmission mode, stable and reliable movement speed

The unique MAG welding two-way backing welding process can meet the complex and changeable working conditions to the greatest extent

Double water cooling method is adopted to facilitate the welding process of filling cover surface with large pipe diameter and large wall thickness

Short distance wire feeding system structure design, smooth wire feeding

中文

中文