Huahengs unique welding process - TIG primer

发布日期:2022-05-20 作者: Kunshan Huaheng Welding Co., Ltd. 点击:

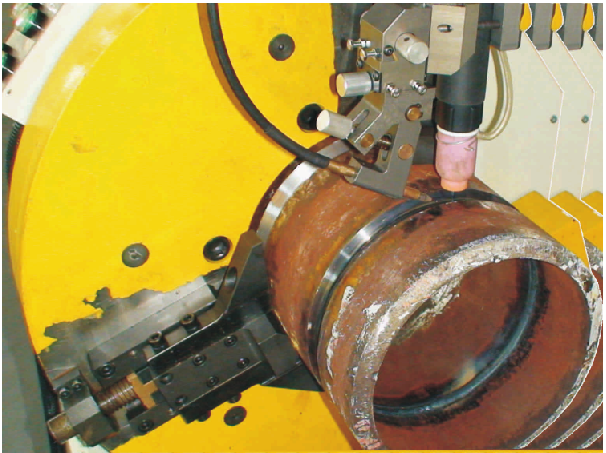

Huaheng welded pipe prefabrication automatic TIG bottoming process is the only one in China that has truly realized single-sided welding and double-sided forming process in the field of pipeline prefabrication, reaching the international advanced level, and the grouping requirements are the lowest in the industry.

|  |

|  |

Huaheng Welding TIG bottom welding - conditions to be met:

1. TIG's arc length control technology;

2. The pipe wrench of the patented technology product developed to prevent the axial movement and radial movement of the pipeline during the rotation process is the key equipment for realizing TIG bottom welding;

3. Mature welding process is a necessary condition;

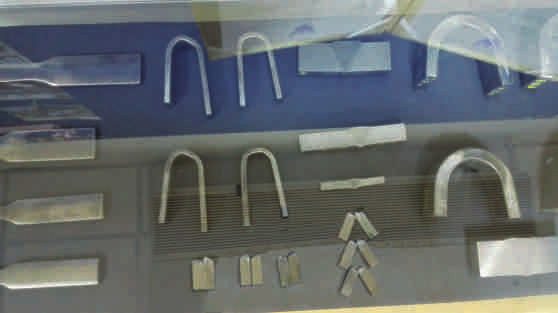

4. Cold-worked grooves and special grooves machined grooves;

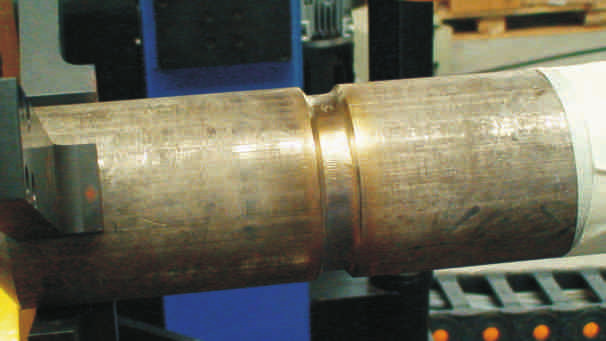

5. The maximum amount of misalignment is less than or equal to 2mm;

6. The gap control is 0-3mm, that is, no gap pairs and gap pairs.

|  |

Advantages of Huaheng Welding TIG bottoming welding process

1. Good quality, because no flux is used, slag inclusion can be reduced;

2. The welding gas seal is better, which can effectively reduce the welding seam pores;

3. It can control the heat input well, a good way to connect sheet metal and bottom welding.

Huaheng's unique welding process-TIG bottoming truly realizes single-sided welding and double-sided forming in the pipeline prefabrication system. Welcome your consultation.

中文

中文