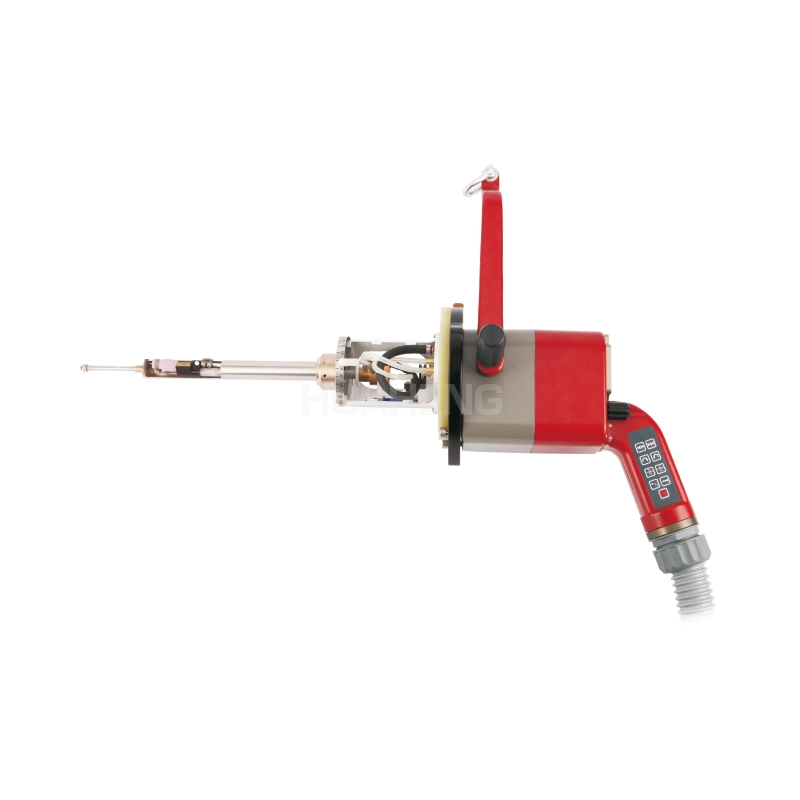

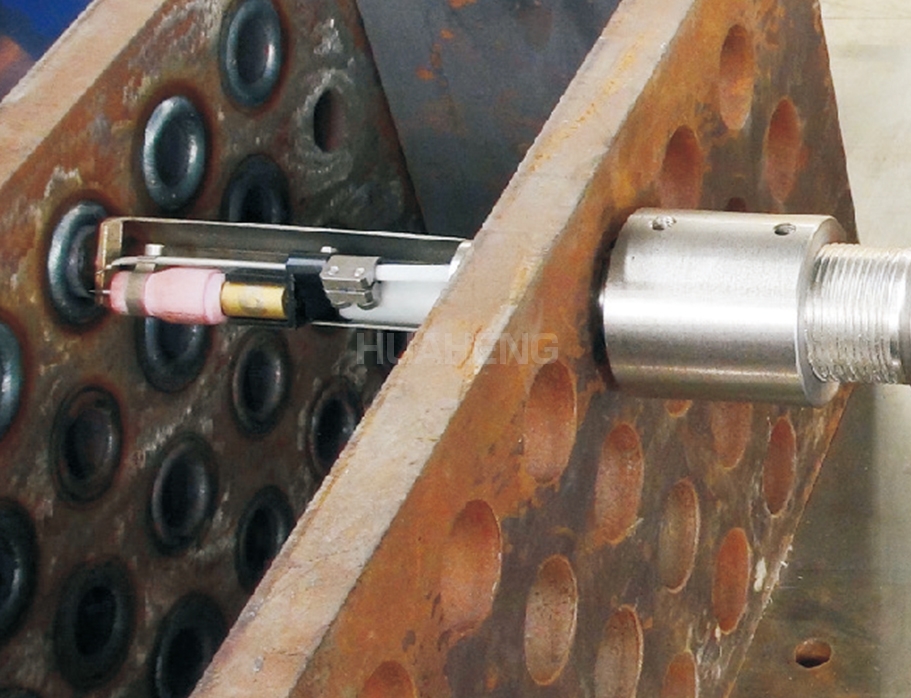

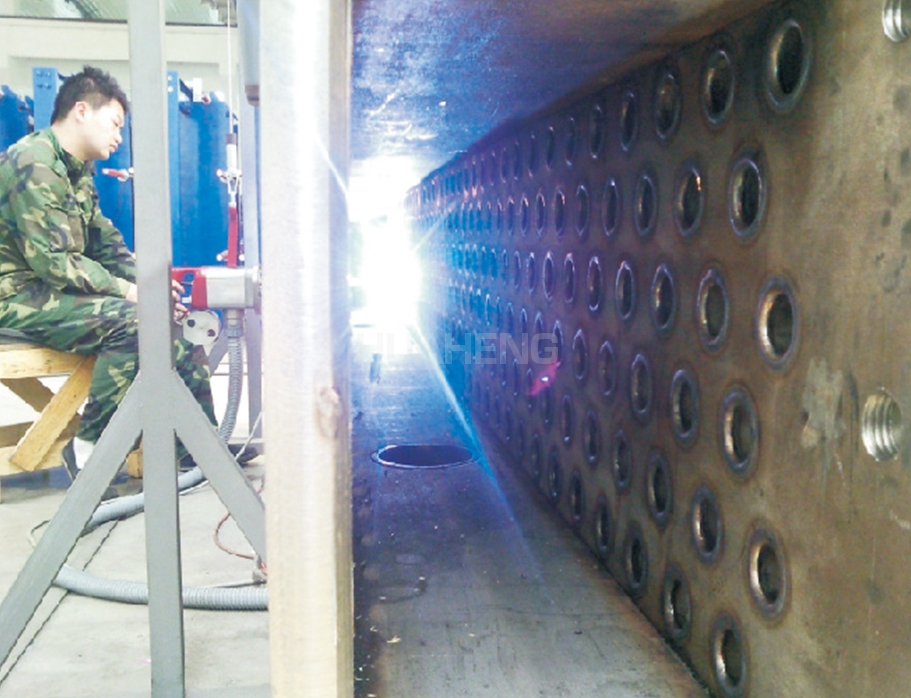

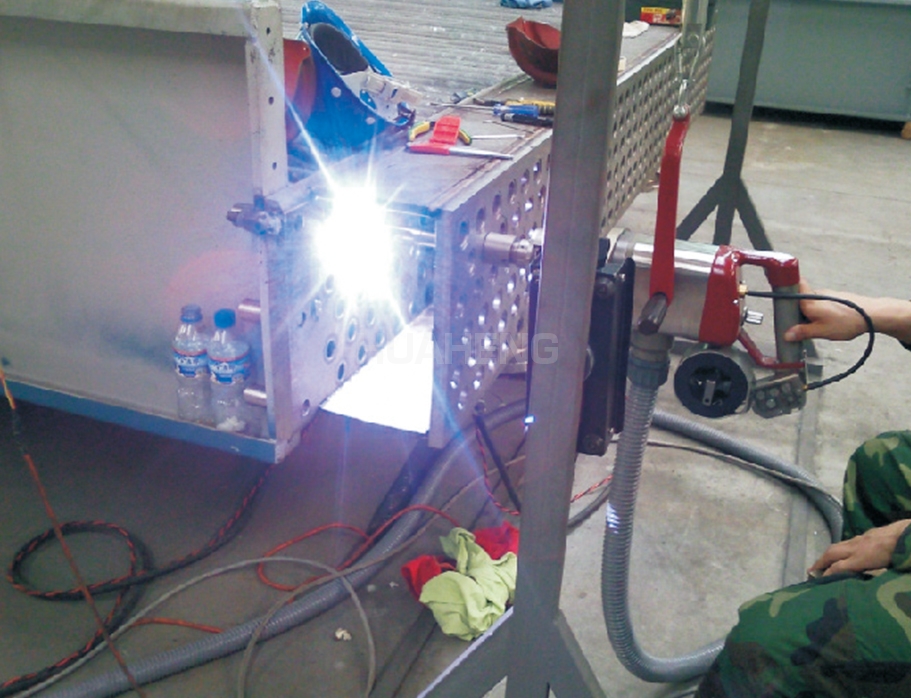

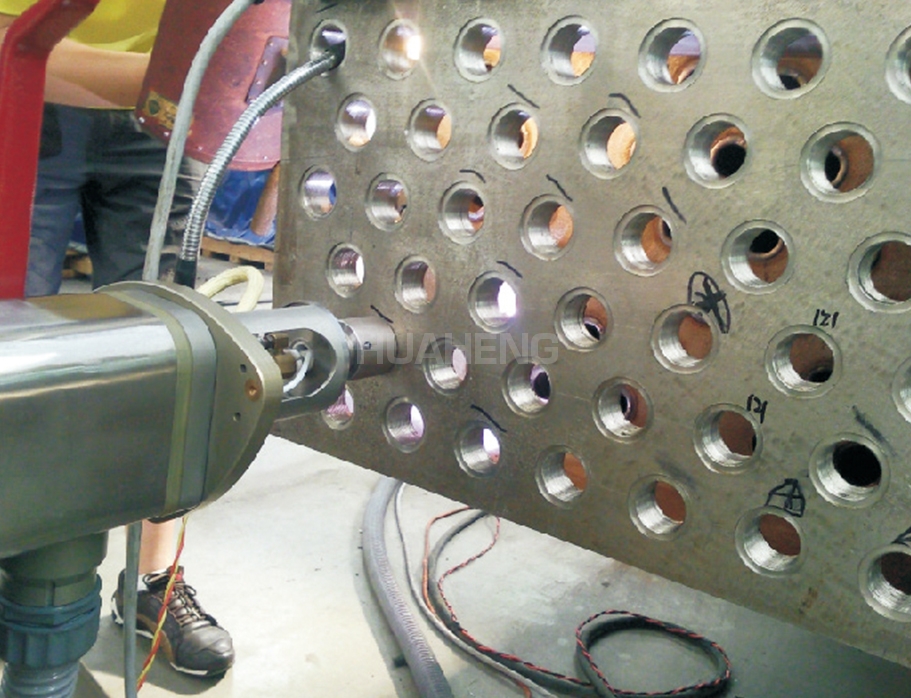

This welding head is specially designed for fully automatic TIG welding of deep hole tubes/tube sheets.Suitable for automatic welding of special tube sheet forms.It can weld carbon steel,stainless steel and other tube sheet joints in the form of tube flush joints.The diameter of the weldable tube isΦ25mm andΦ32mm,and two methods of wire filling or self-melting can be used.This machine can be used with iOrbital5000 program-controlled welding power source,which can precisely realize orbital TIG deep hole welding,with high reproducibility of welding results and ideal welding results.It is suitable for automatic welding of special tube sheet forms in boilers,heat exchangers,electric power construction,chemical industry and other industries.

According to the invisibility of deep hole welding,an automatic arc length control device is specially designed,which automatically corrects the arc voltage by collecting the arc voltage signal feedback principle to maintain a stable distance between the tungsten electrode and the welding surface and automatically adjust the arc length.The arc length can be adjusted manually by turning off the automatic arc length control function;

The automatic lifting function of the workpiece is adopted to ensure the consistency of the height of the tungsten electrode and the workpiece during each welding;

With special torch concealment and torch revealing functions,it is convenient for torch insertion and welding;

Weldable material | Carbon steel, stainless steel |

Weldable pipe diameter(mm) | Φ25 or Φ32(mark match Φ25) |

Maximum extension length(mm) | 230(Including plate thickness) |

Tube sheet form | Tube flush |

Tungsten electrode diameter(mm) | Φ2.4 |

Spinning speed(rpm) | 0.37~7.39 |

Torch inclination | -3° |

Arc length adjustment spacing(mm) | 18 |

Maximum wire feed speed(mm/min) | 1800 |

Wire diameter(mm) | Φ0.8 |

Protective gas | Argon |

Cooling method | water cooling |

Cooling flow(ml/min) | ≥300 |

Rated current | 200A duty cycle 60% |

Weight(kg) | 13(without cable) |

Dimensions(mm) | 780×290×310 |

中文

中文