Application Information

With the continuous and long-term development of the high-voltage switchgear industry, SF6 metal-enclosed combined electrical appliances, known internationally as "Gas Insulated Switchgear", or GIS for short, play an extremely important role in power transmission and transformation projects. Circuit breakers, sub-busbars and their equipment casings usually use aluminum-magnesium alloys as the base material. Aluminum alloy shell is one of the main products of GIS.

Power start bus condition:

Workpiece material: 5052 aluminum magnesium and other aluminum alloys

Workpiece wall thickness: below 16mm

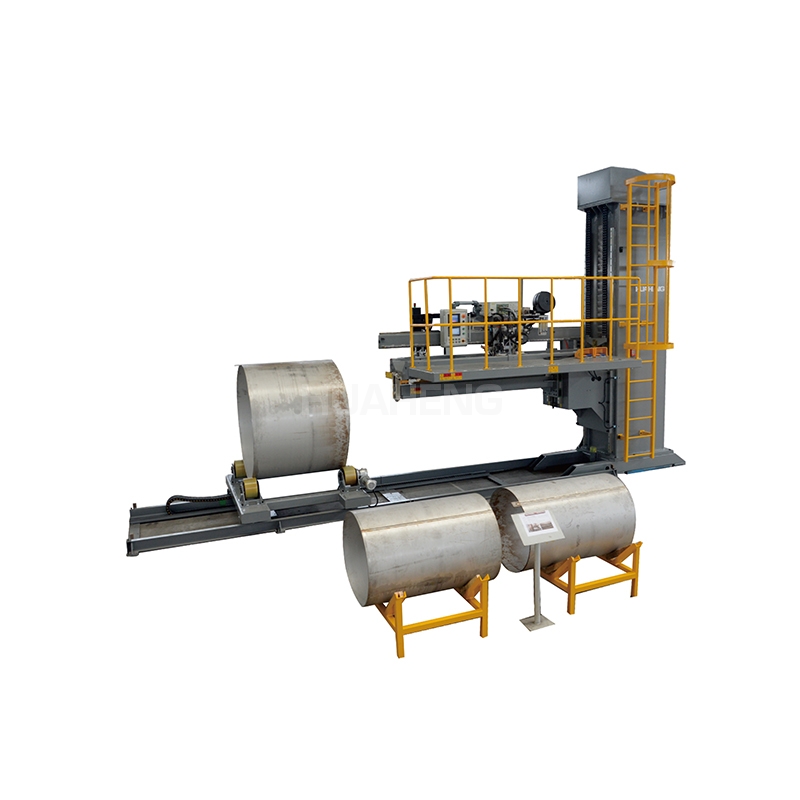

Workpiece diameter: below φ1000mm

Structural form: cylinder longitudinal seam, circumferential seam butt joint, inner and outer fillet welds of pipe flanges

Welding requirements: X-ray filming grade II qualified

Welding process and method

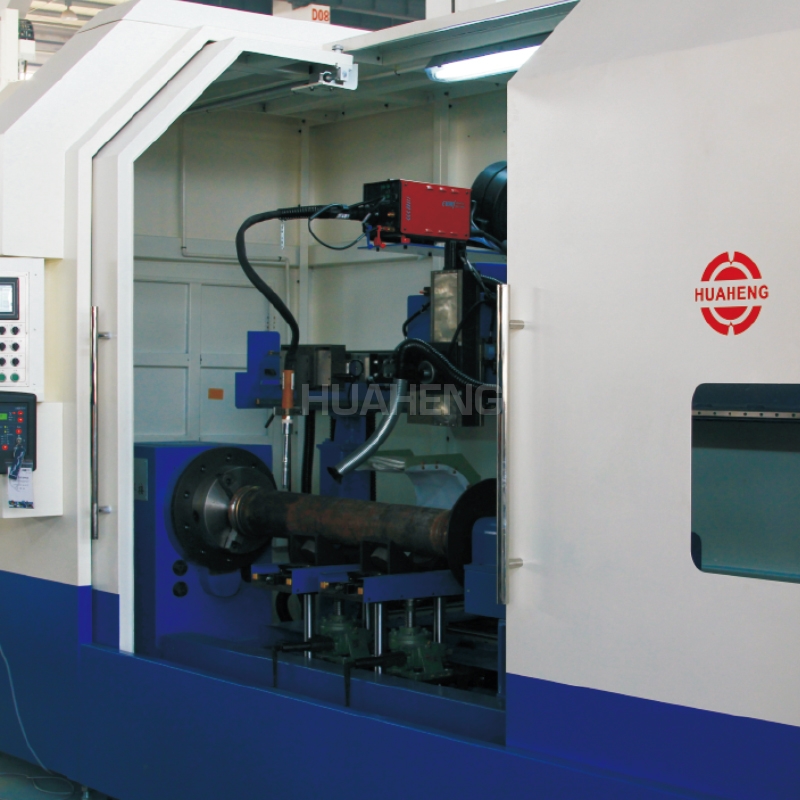

Welding method: Due to the fast heat conduction of aluminum alloy, the pulse MIG welding process method with concentrated energy is adopted, on the one hand, the working conditions and the welding seam forming are improved; on the other hand, the working efficiency is greatly improved. Sometimes in order to further improve the weld surface shape, AC TIG is used to modify the cover.

Welding process characteristics: Through the welding expert parameters built in the digital power supply, under any welding current conditions, a stable one-pulse-one-drop transition can be achieved, and a uniform and beautiful welding seam can be obtained from the surface, and the welding seam can also be reduced for aluminum alloys. Metal overburning, improving weld metal properties. To improve forming, a double-pulse MIG welding process can be applied, resulting in the same weld forming as TIG.

Welding gas: argon or argon plus helium (good for aluminum welding, the composition is 30% or 50% helium, the rest is argon)

Welding diameter: φ1.2 or φ1.6, welding wire grade: ER5356, etc.

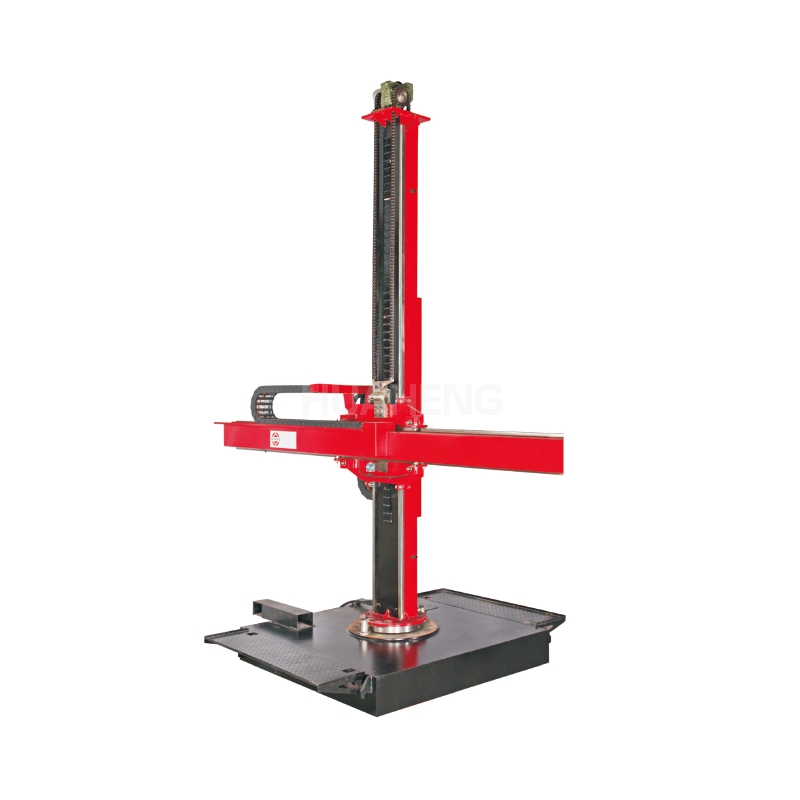

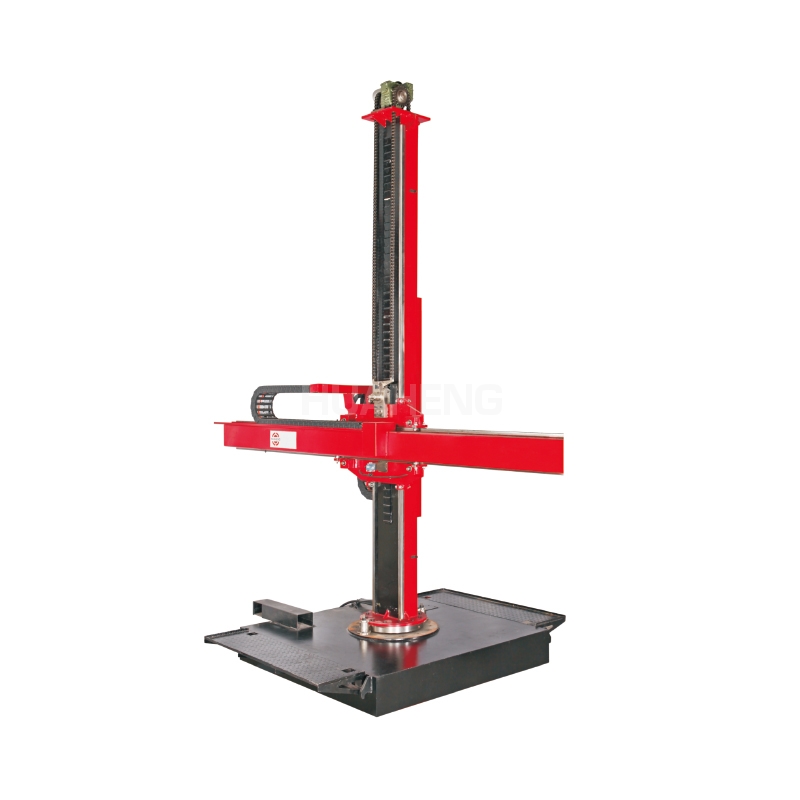

The longitudinal seam is completed on the longitudinal seam special machine, and it can also be completed on the welding center. The welding center is composed of a welding operation frame, a tiltable roller frame and a positioner. seam welding.

中文

中文